Artificial intelligence and machine learning have transformed just about every branch of science and engineering over the last decade or so, and materials science is no exception. U of T’s new Acceleration Consortium is poised to take this transformation to the next level, spearheading the rapid development of new, more efficient and more environmentally sustainable materials.

The consortium – a U of T-based global coalition of academia, industry and government designed to harness advances in materials science, robotics and AI to speed the discovery process – will bring new products to market much faster and far more economically than ever before, according to its director, Alán Aspuru-Guzik, the Canada 150 Research Chair in Theoretical and Quantum Chemistry.

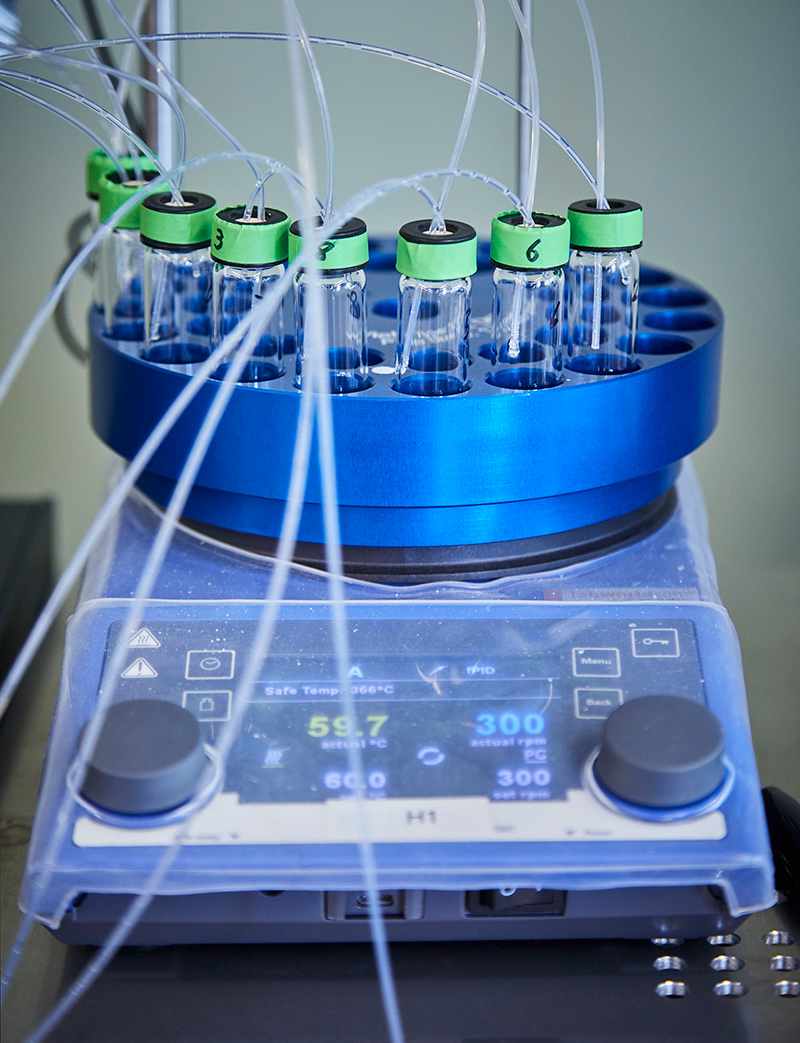

The way Aspuru-Guzik sees it, the laboratory of the future should be like a self-driving car: a lot of expertise goes into setting it up and human scientists still play a vital role in selecting projects and evaluating results. But, to a large extent, the lab should run itself. “What we really want are autonomous labs that can make decisions as they go along.” AI and machine learning are game changers, he says, that can speed up every stage of the development process. “A new field is being born – the field of accelerated science.”

One area where these new materials hold enormous potential is in developing next-generation electronics, including those that are biodegradable. Helen Tran, an assistant professor of chemistry who works with the consortium, sees applications for such devices in fields ranging from medical diagnostics to environmental monitoring. She’s especially interested in polymers – long chain-like organic molecules in which certain groups of atoms repeat. By manipulating the order and connections of atoms in these molecules, their properties can be finely controlled – making them softer or more stretchable as desired. Best of all, they can be designed to simply erode into harmless organic molecules when the time comes. “I see myself as a molecular architect,” says Tran. “We design these molecules one at a time.”

A new field is being born – the field of accelerated science.

In that design process, Tran relies on what is already known about how molecular structure influences electronic properties, as well as her own intuition. But automation speeds everything up. AI helps her and her colleagues “make better-informed decisions about how to design the best molecule for a particular application.”

Tran foresees a myriad of uses for these materials. Think of someone getting an electrocardiogram: A technician sticks an array of electrodes made of plastic and metal on the patient’s chest; when it’s over, the electrodes are tossed in the garbage. Instead, Tran envisions ultra-thin, electrically conducting stickers performing the same function wirelessly, and then degrading safely. “Instead of finding out, years from now, that these electronic stickers are a nuisance, what if we made them from sustainable materials from the beginning?”

For Jason Hattrick-Simpers, a professor of materials science and engineering, the consortium’s work aligns with his own research interests, especially the use of automation and AI to design new alloys and oxides that perform better than those currently used in manufacturing. For example, every year in Canada, more than $60 billion goes into mitigating the effects of the corrosion of metals. There is a human toll, too. Corroded steel reinforcements are thought to have played a role in the collapse of the Miami condominium tower last year that killed 98 people. For Hattrick-Simpers, the investment needed to make steel and other materials last longer is, in the long run, a bargain.

Developing those materials is a challenge – one that requires testing staggering numbers of chemical combinations. He compares his work to that of a cook. “I have this whole list of ingredients –meats, vegetables, spices – and then I have to decide the order in which I add them, how to mix them, whether to boil or fry them. We have the same sort of problem in materials science. There are all these elements we could use, and all these different ways we could bring them together.” Evaluating the seemingly infinite array of combinations is a time-consuming task for a human researcher, but child’s play for an AI. And when humans and AIs work together, projects can be completed in a fraction of the time.

For Aspuru-Guzik, a key to the consortium’s success is bringing together leading experts from around the world and letting the ideas flow. “If you have computer scientists and chemical engineers and materials scientists and chemists in the same consortium, super cool stuff is going to happen.”