With micrometre-level precision, today’s factory robots can assemble thousands of components into a powerful electronic device such as the phone in your pocket. They can perform these intricate and repetitive tasks with great dexterity – in highly controlled settings such as manufacturing plants.

But the world is bigger – and more unpredictable – than a factory floor. Tomorrow’s robots will need to be able to adapt on the fly to changing real-world situations. Consider an autonomous vehicle trying to drive safely through a sudden snowstorm, or search-and-rescue robots seeking earthquake survivors in difficult and shifting terrain. Advances in AI have enabled computers to better understand what they “see” and “hear,” but many challenges remain.

“These are tough problems, but also really exciting ones,” says Hallie Siegel, the associate director of strategy and operations at U of T’s Robotics Institute. Established in 2019, the institute connects about two dozen faculty members, making it one of Canada’s largest research and innovation hubs for robotics and related fields such as AI, controls and sensors. With undergraduate and graduate degree programs, the institute also serves as a training ground for the next generation of robot innovators.

“There is a lot of fundamental research happening in robotics at U of T right now,” says Siegel. “Our faculty and students are working on some of the most challenging questions in the field.”

Here are six ways U of T scientists are helping to advance robotics.

Robots that learn from each other

In controlled environments, robots can perform intricate tasks, but they are less adept in situations they have not been programmed for. Animesh Garg, an assistant professor of math and computer science at UTM, wants to help build robots that can perceive and adapt to new circumstances so they perform better in the real world. Garg is crowdsourcing datasets of successful robot operations in numerous environments, and using an algorithmic approach called “imitation learning” to enable robots to learn from each other. If a robot programmed to operate in a kitchen finds itself in an unfamiliar place, it can learn from the experience of a robot that has operated in a similar context in the past.

Autonomous vehicles that work in any weather

Autonomous vehicles will need to “see” and react appropriately to cyclists, pedestrians and other cars with perfect accuracy – even in difficult road conditions such as dense fog, blowing snow or torrential rain. Steven Waslander, an associate professor at the Institute for Aerospace Studies, is using AI to improve how cameras see “through” the weather. By combining this technology with other sensors, such as Light Detection and Ranging (LiDAR), Waslander is able to improve the identification of hazards on the road, even in low-visibility conditions that can cause other sensors to fail.

Robotic “skin” that could aid in rehabilitation

Traditional robots are made of rigid materials such as steel and hard plastic, but softer materials could help usher in a new generation of robotic technologies worn directly on the human body. Xinyu Liu, a professor of mechanical and industrial engineering, uses stretchable soft plastics to create a novel kind of robotic skin. “iSkin” can convert physical movement into electrical impulses, which allows it to monitor vital signs and measure the body’s range of motion. It can help track injury rehabilitation more precisely, and in the future, might be used as part of exoskeleton suits that provide extra support to muscles and speed up rehabilitation from injuries or strokes.

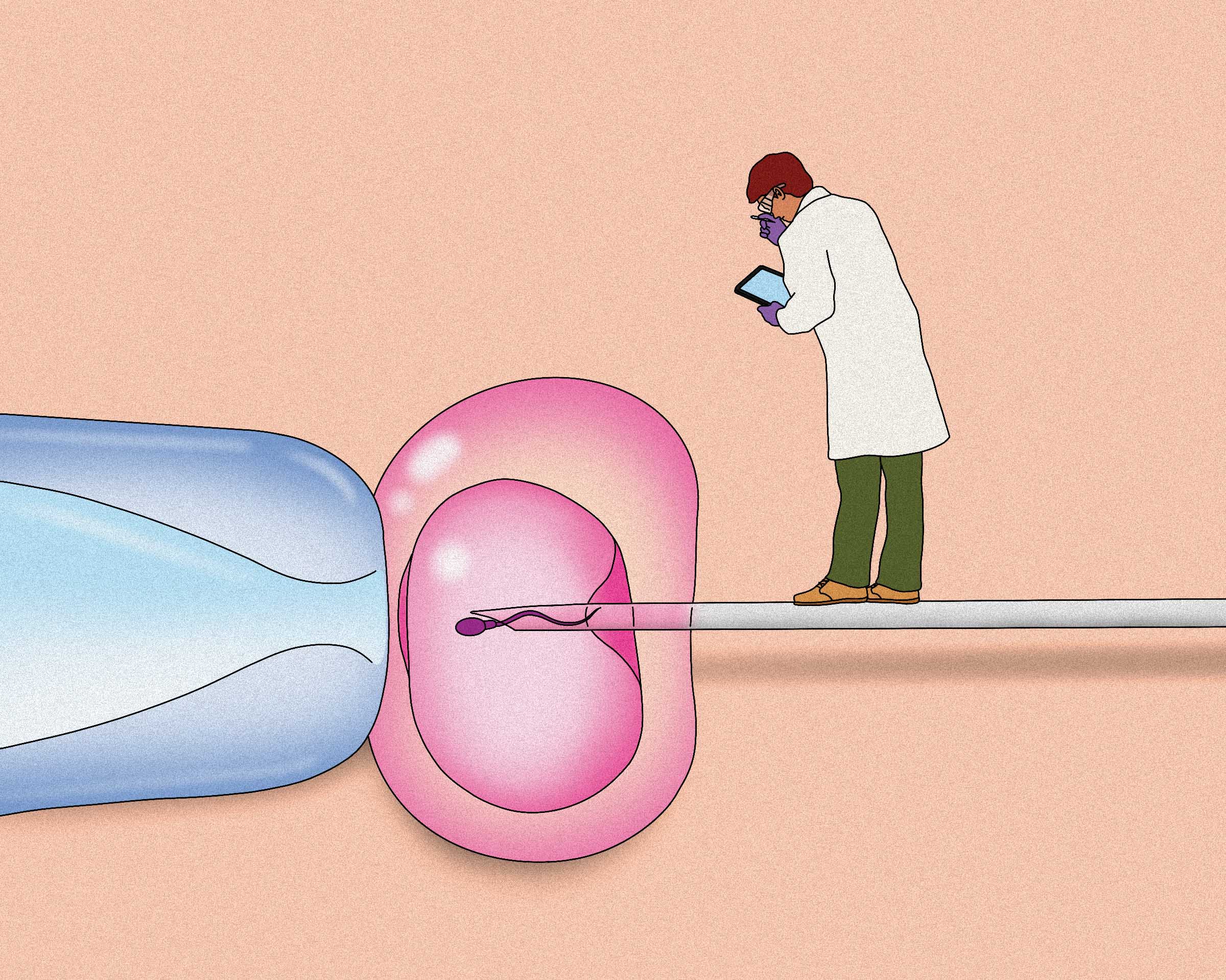

A robotic system to boost the success of in vitro fertilization

In vitro fertilization is a complex – and often unsuccessful – procedure that can cost tens of thousands of dollars. (Fewer than a third of all IVF treatment cycles lead to a live birth.) Yu Sun, the director of U of T’s Robotics Institute, is using robotics and AI to improve this success rate. He has developed a computer vision algorithm and AI to select sperm with the least damaged DNA (based on parameters from the World Health Organization). Once this single sperm cell is selected, his robotic system immobilizes it and draws it into an extremely fine needle. An ultra-precise robotic hand then inseminates the sperm into an egg through repeated, gentle taps on the egg’s elastic membrane – like a minuscule woodpecker tapping on the bark of a tiny tree.

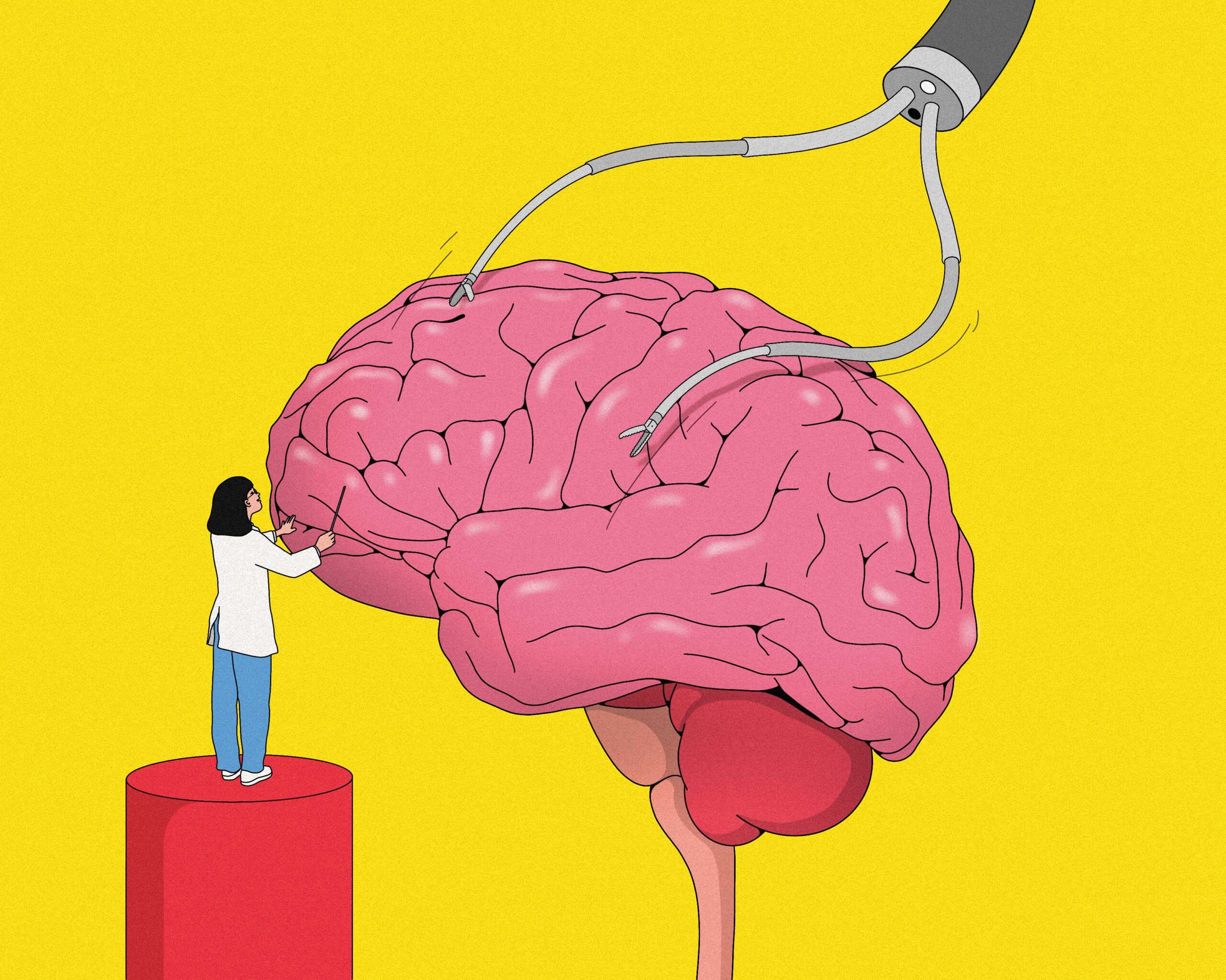

Tiny robots to assist with surgery

Surgeons already use robotic assistance to eliminate hand tremors when performing open heart surgery, but Eric Diller, an associate professor of mechanical and industrial engineering, is working on tiny robots that could soon be used to make brain surgery less invasive. He is developing a gripper robot that is only a few millimetres wide that can be controlled wirelessly with electromagnets. Inserted through a small borehole in the skull, the robot can grasp, pull and cut, and one day could be used to remove some brain tumours, for example, or deliver targeted epilepsy treatments – speeding recovery time and lowering costs.

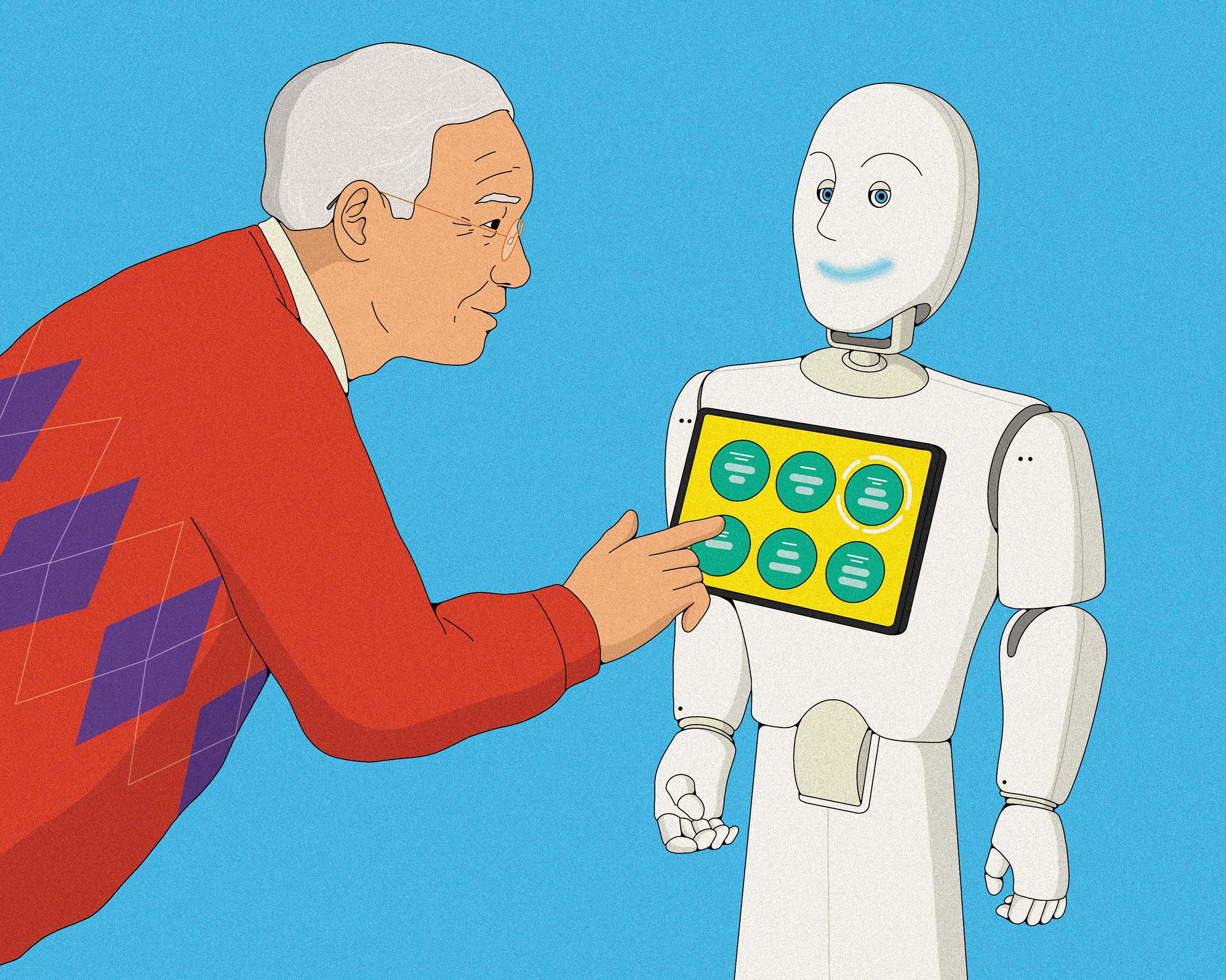

Social robots to help seniors live independently

Dementia is often a factor when people transition into long-term care, but robots can help seniors age in the comfort of their own homes. Goldie Nejat, a professor of mechanical and industrial engineering and the Canada Research Chair in Robots for Society, is developing socially assistive robots designed to prolong independent living. Nejat’s in-home robots can help seniors get dressed, exercise and play memory games. Her team has also developed a social robot that assists older adults in the kitchen by suggesting recipes and meal preparation steps, and even reminding them of where the ingredients are stored.

Snake-like robots that flex and extend

Jessica Burgner-Kahrs, the director of the Continuum Robotics Lab at U of T Mississauga, and her team are building slender, flexible and extensible robots, a few millimetres in diameter, for use in industry and surgery. Unlike humanoid robots, so-called continuum robots feature a long, limbless body – not unlike a snake’s – that allows them to access difficult-to-reach places. Burgner-Kahrs envisions a day when a surgeon might use one to take a winding path around vital tissue in the brain but still reach a precise surgical site. A continuum robot could also slide through the interior of a jet engine, inspecting it for damage. The lab is experimenting with novel forms that are even more dexterous and extensible. One recent design, with potential in search-and-rescue applications, is inspired by origami: it’s very light, and can elongate up to 10 times further than other designs.

Recent Posts

People Worry That AI Will Replace Workers. But It Could Make Some More Productive

These scholars say artificial intelligence could help reduce income inequality

A Sentinel for Global Health

AI is promising a better – and faster – way to monitor the world for emerging medical threats

The Age of Deception

AI is generating a disinformation arms race. The window to stop it may be closing